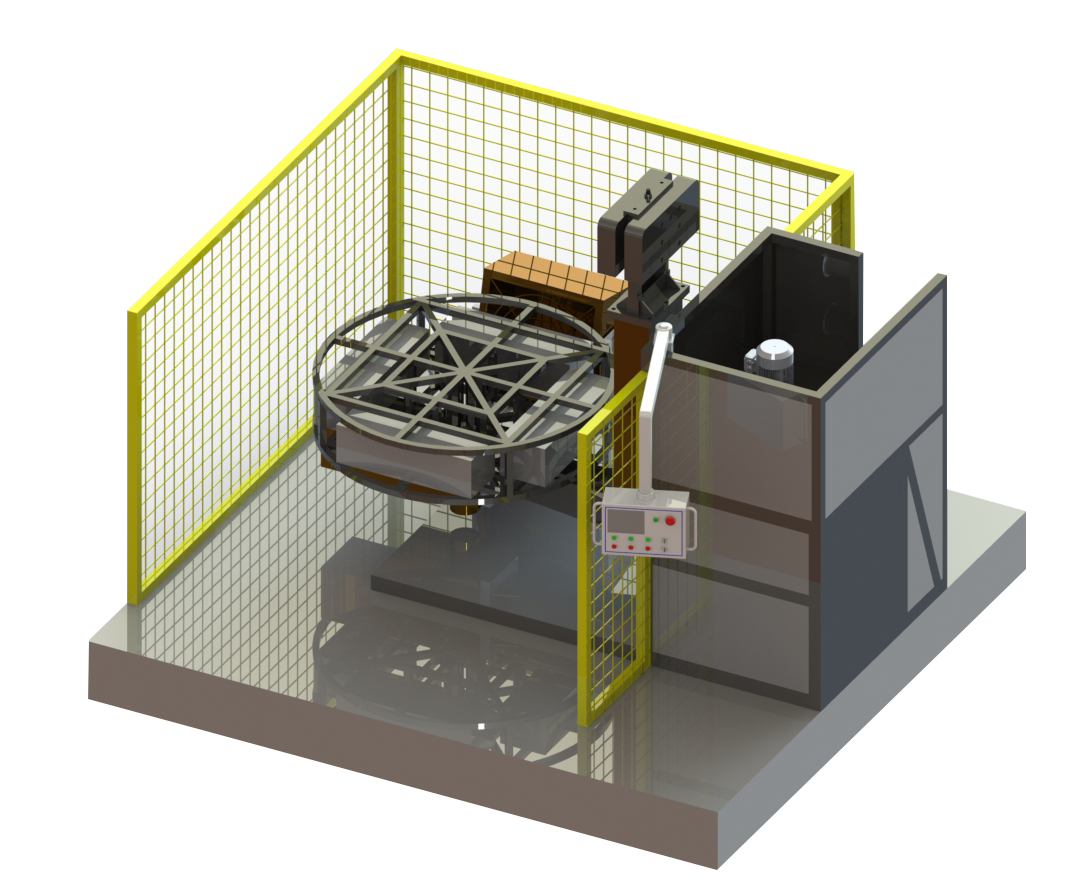

Electrical Heating Rotational Machine

Advanced machinery for industrial applications

Electrical Heating Rotational Machine - Efficient and Energy-Saving Rotomolding Solution

Product Overview

The Electrical Heating Rotational Machine utilizes advanced electric heating technology, featuring high efficiency, energy savings, stability, and ease of operation. This machine is ideal for producing various plastic products, especially medium and small-sized items. Compared to traditional gas heating systems, the electrical heating rotomolding machine not only reduces fuel consumption but also provides more precise temperature control, ensuring high-quality products and a stable production process.

Key Features:

Electric Heating Technology: The machine uses an advanced electric heating system that provides an efficient, energy-saving heating method, reducing energy consumption and lowering production costs.

Precise Temperature Control: Equipped with an advanced temperature control system, this machine allows for precise temperature regulation, ensuring product consistency and high quality.

Stable and Reliable: The high-quality electric heating elements ensure the long-term stability and reliability of the machine.

Environmentally Friendly: Reduces fuel consumption, lowers emissions, and meets environmental standards, making it an ideal choice for green production.

Intelligent Control: The machine is equipped with a PLC control system, which precisely regulates the current and heating time to optimize energy consumption and improve production efficiency.

Mechanical Parts:

Electric Heating System: Provides more than 9 heating units, supplying the appropriate heat source according to mold size, ensuring stability during the heating process.

Intelligent Control System: Uses a PLC control system to precisely regulate current and heating time, optimizing energy consumption and boosting production efficiency.

Efficient Hot Air Circulation System: Ensures even heat distribution and prevents local overheating, improving production efficiency.

Thermal Insulation Design: High-quality insulation materials inside the machine reduce heat loss and enhance heating efficiency.

Applications:

The electrical heating rotomolding machine is widely used in various industries, particularly for producing medium and small plastic products. Typical application areas include:

Automotive Parts: For manufacturing various car parts such as bumpers and dashboards.

Furniture: For producing plastic chairs, tables, storage cabinets, etc.

Sports Equipment: For items such as skateboard decks, yoga mats, etc.

Educational Tools: For creating educational models, laboratory equipment, and more.

Water Sports Products: Such as swimming pools, life rafts, etc.

Kitchenware: Including plastic utensils, cooking tools, and trash bins.

Advantages:

Energy-Efficient: The electric heating system is more energy-efficient than traditional gas systems, resulting in lower operating costs.

Strong Environmental Benefits: No smoke or waste gas emissions, complying with international environmental standards.

Consistent Product Quality: Precise temperature control ensures consistent product quality for every batch.

Easy to Operate: The intelligent control system makes it easy for operators to adjust and monitor the production process.